Fabrication & Welding Services

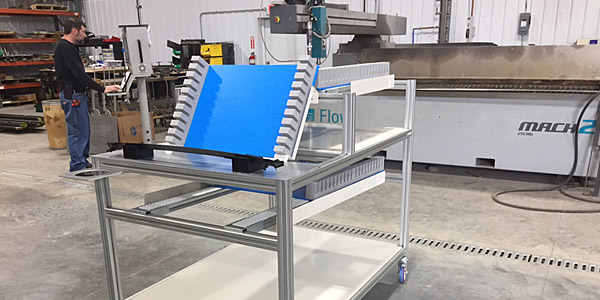

Special Mine Services offers a fully-functional welding and fabrication department, complete with a staff of engineers, welders, and technicians. Possessing some of the latest equipment from Flow, AccurPress, Aida and Lincoln. We combine the best of these new technologies with SolidWorks design software and a team dedicated to customer service. Offering a wide variety of services on a range of materials, Special Mine Services is ready to supply your personalized welding and fabrication needs today.

- Mig Welding – Metal Inert Gas is an arc welding process that uses a continuous solid wire electrode heated and fed into the weld pool from a welding gun. Often used on thicker material easy to get too.

- Tig Welding – Tungsten Inert Gas is an arc welding process that requires the fillet to be hand fed into the arc of the torch. It’s a slower process used for more delicate and thinner materials as well as tight areas.

- Water Jet – A stream of water highly forced through a small aperture to cut through materials. It can be used on a wide variety of materials and thicknesses.

- Laser Cutting – Technology that uses a laser to vaporize materials, resulting in a cut edge. Used typically for industrial manufacturing applications.

- Shearing Metal – Process used to cut flat metal sheet without the formation of chips or the use of burning or melting material.

- Cutting Metal – Process used mainly on round or bar stock to separate material into its desired length.

- Punch Press – Using a die this can change the shape or size of a piece of metal.

- Forming – Process in which force is applied to shape a piece of metal to its desired shape.

- Bending – Process in which round or square stock is curved from its straight state.

- Notching – Process in which material is removed from one piece of material to mate it to another for a blended fit.

- Surface Grinder – A abrasive machining process in which a spinning wheel covered in rough particles cuts chips of metallic or nonmetallic substance from a workpiece, making a face of it flat and smooth.

- EDM – Electrical Discharge Machining which allows small workpieces to be produced that could possibly be damaged from conventional cutting tools. There is no direct contact between the tools and material. Capable of doing very complex parts.

- CNC Milling – A manufacturing process that used cutting a tool mounted on a rotating spindle to selectively remove material from a block of raw material.

- CNC Lathe – A machine tool where the material is held in place and rotated by the main spindle as the cutting tool works on the material is mounted and moved on various axes.

- Heat Treatment – Using heat at various staged levels to change the physical properties of a metal. Mainly used on steel or aluminum.

- EOAT – End of Arm Tooling are devices that can be installed on a robotic arm or wrist to expand the robot’s industrial capabilities.

- Assembly – Process of taking several different components, combining them together to make a final product. With capabilities of making projects turn-key (Electrical, pneumatic and hydraulic).